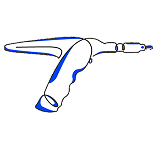

The first-known battery-operated, affordable standalone footplate to turn a craniotomy flap. Watch our video here: Phasor FLIP (Footplate)

Designed for Practicality, Versatility, Safety, and Success over Failure

A technological breakthrough relying upon battery-operated free-standing drills, the ability to turn a craniotomy flap with this portable device, equipped additionally with a quick-connect mechanism for bit interchangeability, is a novelty – which stands to translate into success vs. failure in a life-threatening situation.