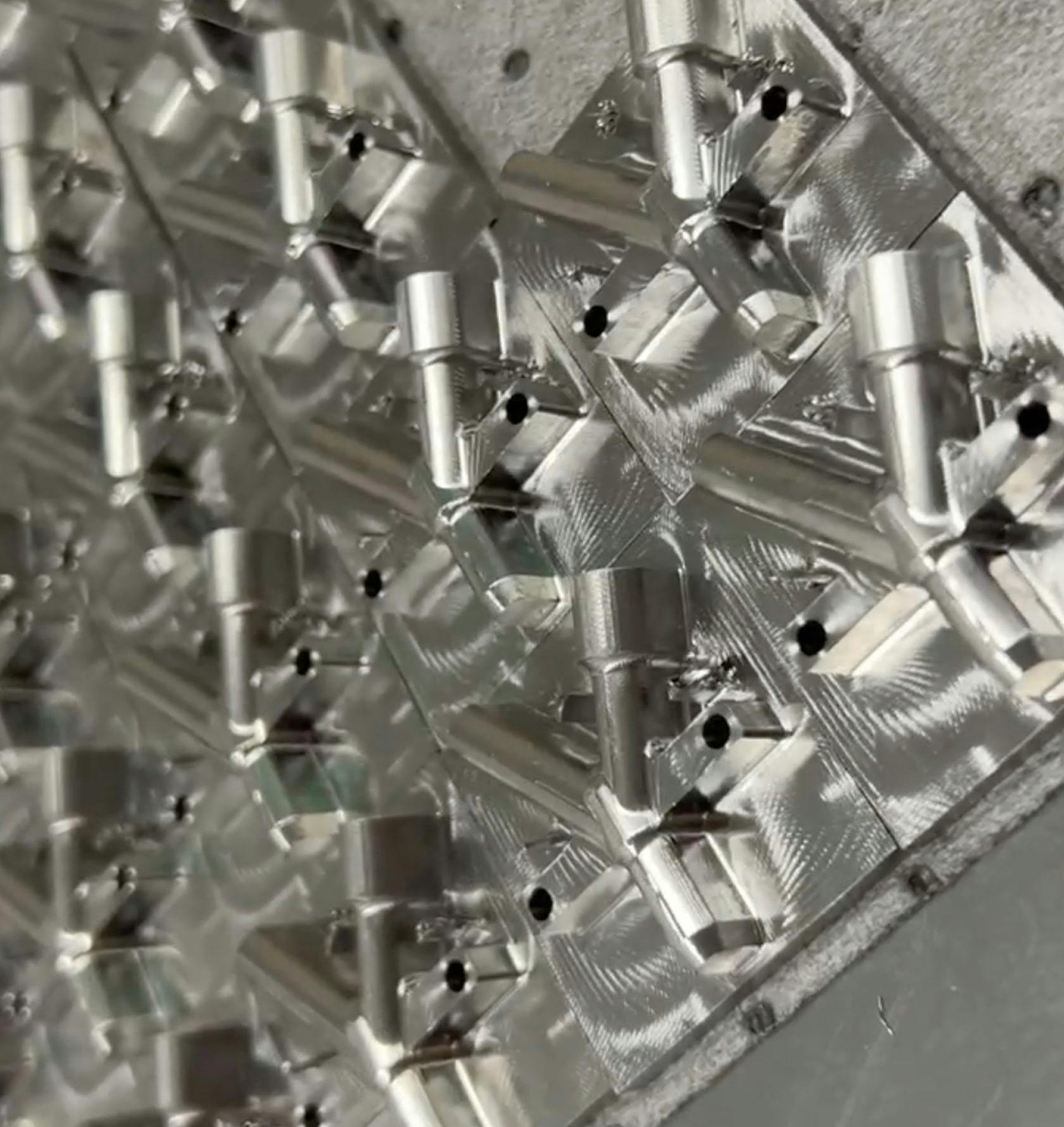

Precision-engineered in the United States for safety, reliability, and clinical performance.

Setting a Higher Standard for Device Manufacturing

Phasor Health’s U.S. manufacturing model is built around control, quality, responsiveness, cost-efficiency, and a “special forces” mindset: the power of a few, dedicated individuals can accomplish more than large masses with proper focus and unrelenting commitment. By controlling every step of the process, the company protects hospitals and patients from variability that may compromise outcomes.

Every unit represents Phasor’s core promise: safety without compromise and feed-forward performance without delay.